Technology

Pre-Printing

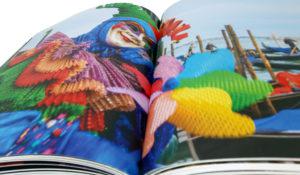

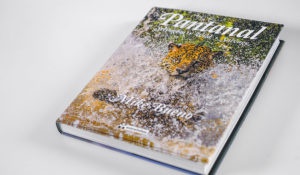

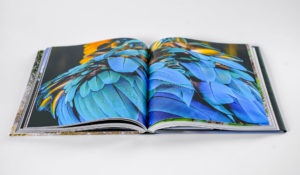

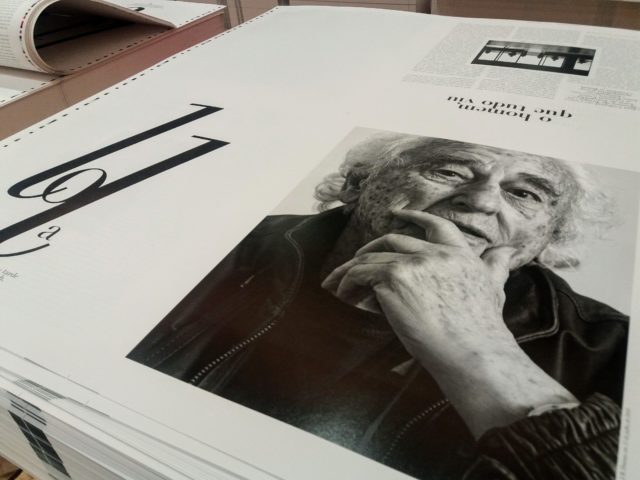

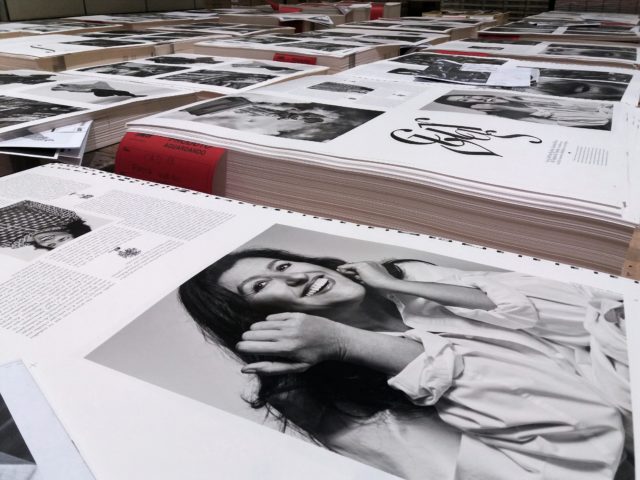

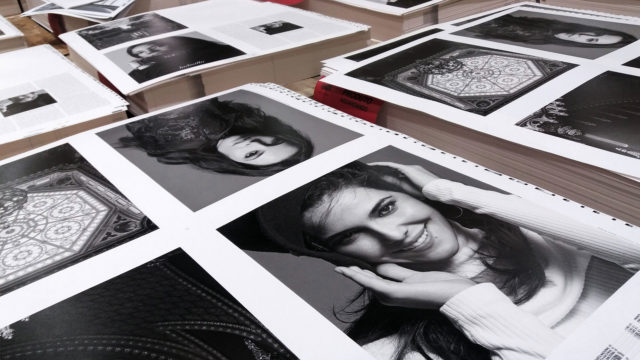

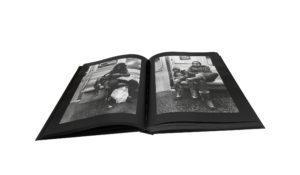

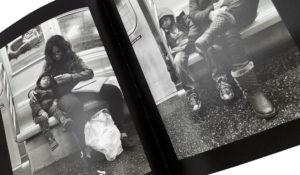

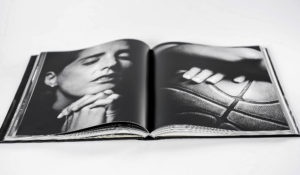

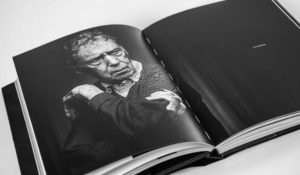

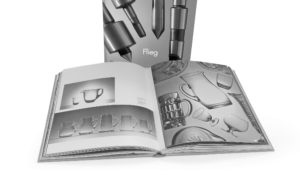

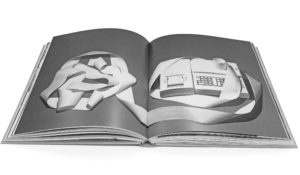

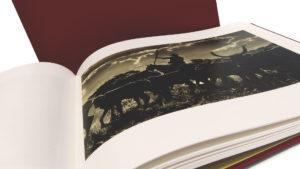

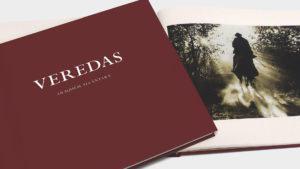

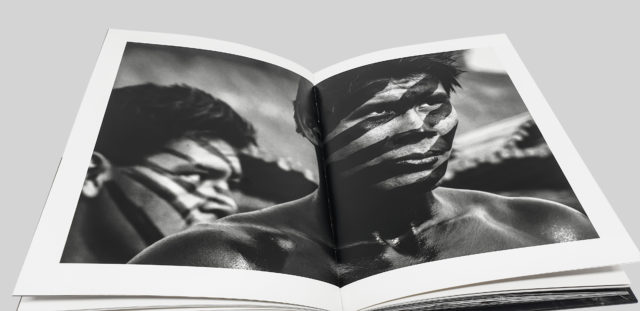

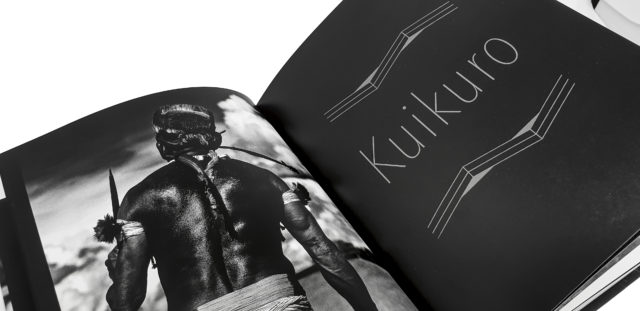

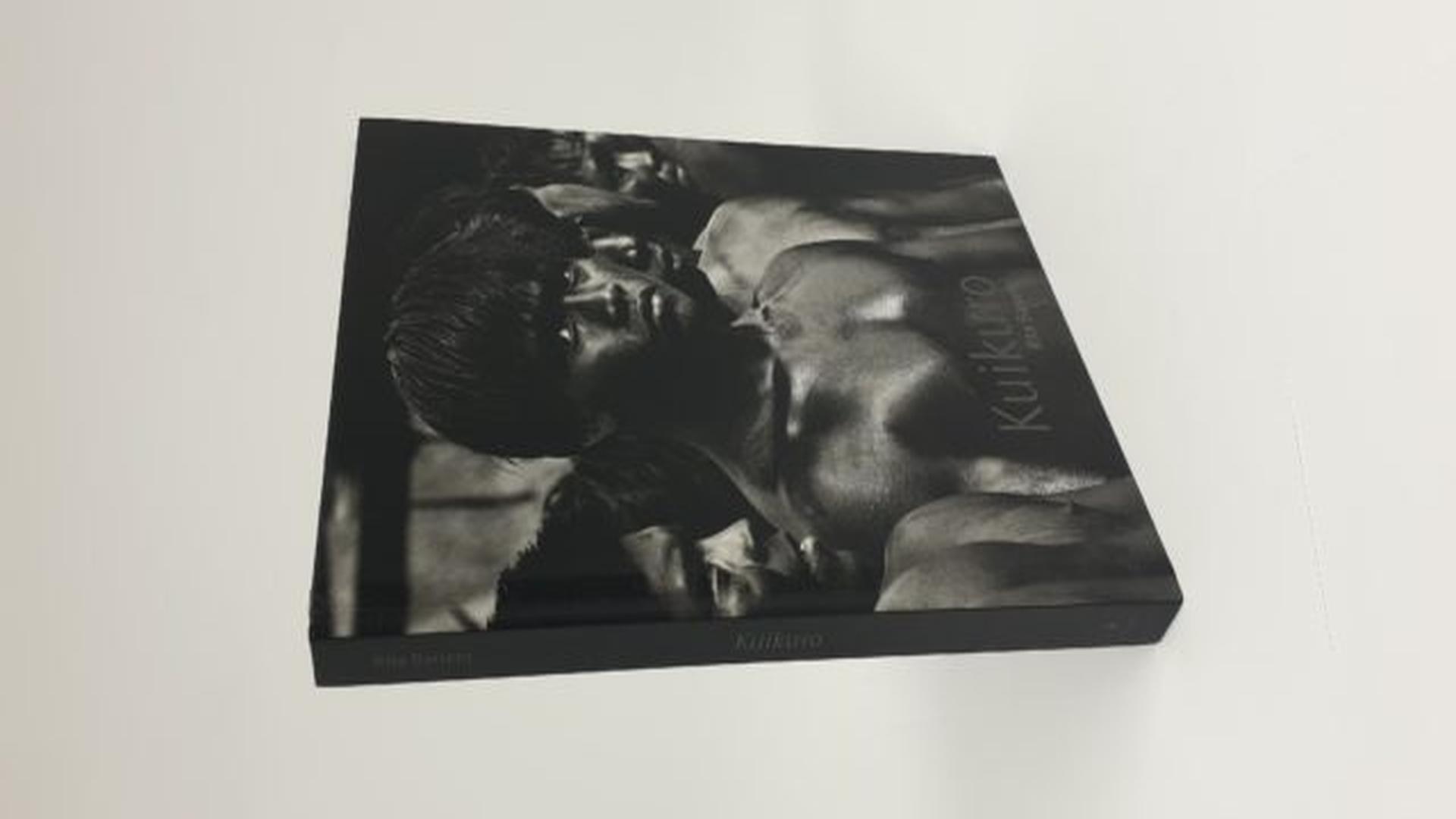

Our clients seek fidelity in transcribing their art onto paper.

The technologies developed by Ipsis make it possible to bring the reality of images and their nuances to paper, regardless of the original, be it fine art, paper, photography, illustration, collage, painting, drawing or any other artistic form.

Discover below the exclusive technologies patented by Ipsis.

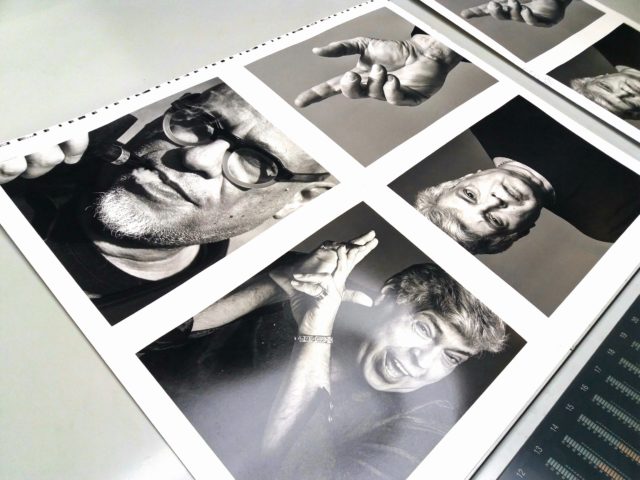

Remote Approval Ease and flexibility to access and approve your work online.

With ease and flexibility to access and approve your work via the web.

Ipsis provides the InSite remote approval tool to assist its Clients in the optimization of time.

The portal allows the review and final approval of your work, replacing the physical proof of content.

The system offers security and confidentiality of the content of the available works, records access history, notifications and changes made.

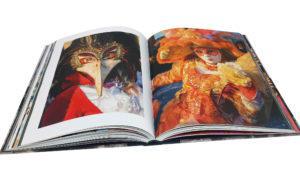

Color Management We have technology to ensure control of the various equipment used during the process to obtain consistency in the result.

The metrology process through monitors, proofing system and calibrated plate engraving, ensure the correct color reproduction in the printing, obtaining the customers’ desired result, with images that stand out for their beauty and level of detail.